|

|

| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 10 sets per month |

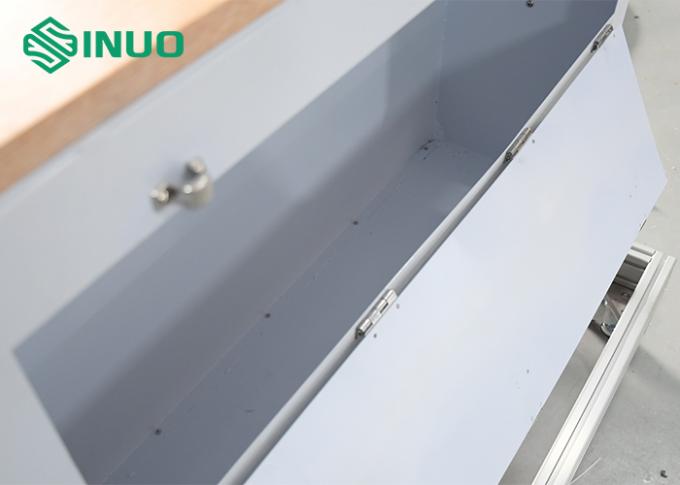

IEC 60884-1 Tumbling Barrel Free Fall Test Apparatus For Plugs And Socket Resistance Test

Product Information:

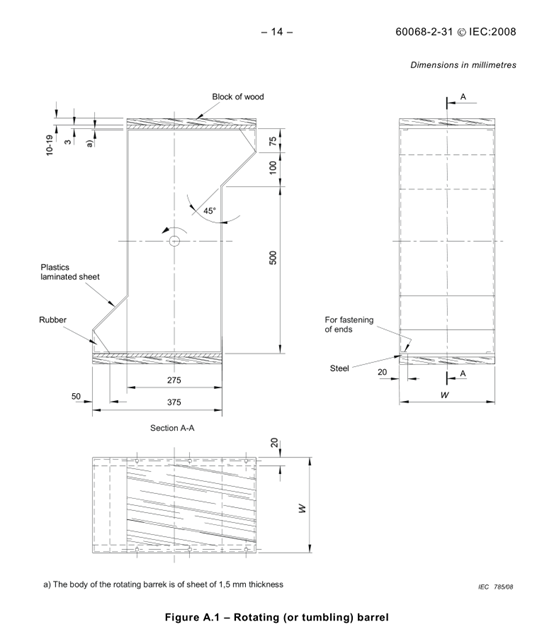

Standard: Conforms to IEC 60598-1 clause 4.13.6, figure 25.

Application: This device is suitable for checking whether plug-ballast/transformers and mains socket-outlet-mounted luminaires have adequate mechanical strength.

Test sample: Plug-ballast/transformers and mains socket-outlet-mounted luminaires.

Feature: This tester can preset test times, automatic stop when set test times completed.

Features:

A tumbling barrel testing machine, also known as a tumbling barrel tester or abrasion tester, is a specialized equipment used to evaluate the resistance of materials, coatings, or products to abrasion, wear, and impact forces. The machine simulates repetitive tumbling or rolling actions to assess the durability and performance of the tested samples. Here are the key features and functions typically associated with a tumbling barrel testing machine:

Tumbling Barrel: The machine consists of a rotating barrel or drum where the samples are placed for testing. The barrel is designed to rotate at a controlled speed and can have a specific shape, such as a cylindrical or hexagonal configuration, depending on the testing requirements.

Sample Holder: The tumbling barrel includes a sample holder or fixture where the test samples are securely placed. The fixture ensures that the samples remain in position during the rotational motion and experience the desired tumbling and impact forces.

Rotation and Speed Control: The machine incorporates a motorized system to rotate the tumbling barrel at a specified speed. The rotational speed can be adjusted to simulate different operating conditions and evaluate the samples' resistance to abrasion and wear under varying velocities.

Test Media: Abrasive media, such as steel balls, ceramic beads, or sand, is added to the tumbling barrel along with the samples. The media acts as the abrasive agent, causing friction, impact, and wear on the samples during the tumbling process.

Test Duration Control: The tumbling barrel testing machine allows for precise control over the test duration. The test duration can be set to a specific number of rotations or a predetermined time period, depending on the testing standards or requirements.

Observation Window: Some tumbling barrel testers feature an observation window or transparent panel that allows users to visually monitor the testing process. This window enables the inspection of the samples during testing to assess the extent of abrasion, wear, or damage.

Safety Features: Safety measures are incorporated into tumbling barrel testing machines to protect the operators and ensure safe operation. These features may include safety interlocks, emergency stop buttons, protective covers, and noise reduction measures.

Tumbling barrel testing machines are commonly used in industries such as manufacturing, automotive, aerospace, coatings, and materials research. They provide a standardized method to evaluate the durability, wear resistance, and performance of materials, coatings, components, and finished products. The testing results obtained from these machines help manufacturers improve product quality, select suitable materials, optimize coatings, and assess the expected lifespan and performance of their products in real-world applications.

Technical Parameters:

| Rotate speed | 5rpm |

| Drop rate | 10 time per min |

| Material | 3mm high quality steel plate |

| Test times | 0~9999 can be preset |

| Drop height | 500 mm |

| Barrel width | 1000 mm (in order to be compatible with user’s big specimens) |

| Barrel number | Single |

| Application | Plug-ballast/transformers and mains socket-outlet-mounted luminaires |

| Standards | IEC 60598-1 clause 4.13.6, figure 25 |

| Power supply | 220V,50Hz |

Test Procedures and Operation Steps:

Plug-ballast/transformers and mains socket-outlet-mounted luminaires shall have adequate mechanical strength.

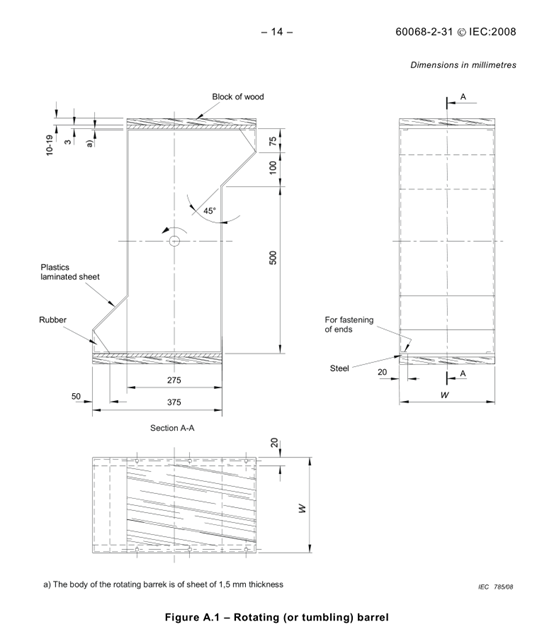

Compliance is checked by the following test, which is made in a tumbling barrel as shown in Figure 25.

The barrel is turned at a rate of five revolutions per minute, ten falls per minute thus taking place.

The sample falls from a height of 50 cm onto a steel plate 3 mm thick, the number of falls being:

– 50 if the mass of the sample does not exceed 250 g;

– 25 if the mass of the sample exceeds 250 g.

After the test, the sample shall show no damage within the sense of this standard, but it need not be operative and any damage to the glass bulb shall be ignored. Provided that the protection against electric shock is not affected, small pieces which may have broken off the

sample are ignored.

Distortion of pins and damage to the finish and small dents which do not reduce the creepage distances or clearances below the values specified in Section 11 are ignored.

|

|

| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 10 sets per month |

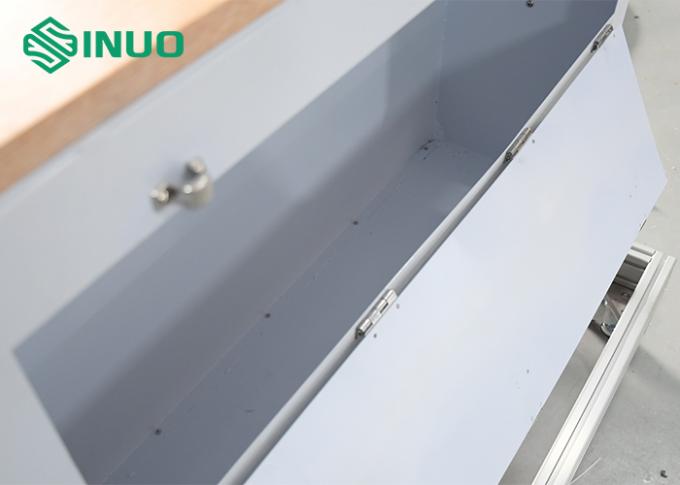

IEC 60884-1 Tumbling Barrel Free Fall Test Apparatus For Plugs And Socket Resistance Test

Product Information:

Standard: Conforms to IEC 60598-1 clause 4.13.6, figure 25.

Application: This device is suitable for checking whether plug-ballast/transformers and mains socket-outlet-mounted luminaires have adequate mechanical strength.

Test sample: Plug-ballast/transformers and mains socket-outlet-mounted luminaires.

Feature: This tester can preset test times, automatic stop when set test times completed.

Features:

A tumbling barrel testing machine, also known as a tumbling barrel tester or abrasion tester, is a specialized equipment used to evaluate the resistance of materials, coatings, or products to abrasion, wear, and impact forces. The machine simulates repetitive tumbling or rolling actions to assess the durability and performance of the tested samples. Here are the key features and functions typically associated with a tumbling barrel testing machine:

Tumbling Barrel: The machine consists of a rotating barrel or drum where the samples are placed for testing. The barrel is designed to rotate at a controlled speed and can have a specific shape, such as a cylindrical or hexagonal configuration, depending on the testing requirements.

Sample Holder: The tumbling barrel includes a sample holder or fixture where the test samples are securely placed. The fixture ensures that the samples remain in position during the rotational motion and experience the desired tumbling and impact forces.

Rotation and Speed Control: The machine incorporates a motorized system to rotate the tumbling barrel at a specified speed. The rotational speed can be adjusted to simulate different operating conditions and evaluate the samples' resistance to abrasion and wear under varying velocities.

Test Media: Abrasive media, such as steel balls, ceramic beads, or sand, is added to the tumbling barrel along with the samples. The media acts as the abrasive agent, causing friction, impact, and wear on the samples during the tumbling process.

Test Duration Control: The tumbling barrel testing machine allows for precise control over the test duration. The test duration can be set to a specific number of rotations or a predetermined time period, depending on the testing standards or requirements.

Observation Window: Some tumbling barrel testers feature an observation window or transparent panel that allows users to visually monitor the testing process. This window enables the inspection of the samples during testing to assess the extent of abrasion, wear, or damage.

Safety Features: Safety measures are incorporated into tumbling barrel testing machines to protect the operators and ensure safe operation. These features may include safety interlocks, emergency stop buttons, protective covers, and noise reduction measures.

Tumbling barrel testing machines are commonly used in industries such as manufacturing, automotive, aerospace, coatings, and materials research. They provide a standardized method to evaluate the durability, wear resistance, and performance of materials, coatings, components, and finished products. The testing results obtained from these machines help manufacturers improve product quality, select suitable materials, optimize coatings, and assess the expected lifespan and performance of their products in real-world applications.

Technical Parameters:

| Rotate speed | 5rpm |

| Drop rate | 10 time per min |

| Material | 3mm high quality steel plate |

| Test times | 0~9999 can be preset |

| Drop height | 500 mm |

| Barrel width | 1000 mm (in order to be compatible with user’s big specimens) |

| Barrel number | Single |

| Application | Plug-ballast/transformers and mains socket-outlet-mounted luminaires |

| Standards | IEC 60598-1 clause 4.13.6, figure 25 |

| Power supply | 220V,50Hz |

Test Procedures and Operation Steps:

Plug-ballast/transformers and mains socket-outlet-mounted luminaires shall have adequate mechanical strength.

Compliance is checked by the following test, which is made in a tumbling barrel as shown in Figure 25.

The barrel is turned at a rate of five revolutions per minute, ten falls per minute thus taking place.

The sample falls from a height of 50 cm onto a steel plate 3 mm thick, the number of falls being:

– 50 if the mass of the sample does not exceed 250 g;

– 25 if the mass of the sample exceeds 250 g.

After the test, the sample shall show no damage within the sense of this standard, but it need not be operative and any damage to the glass bulb shall be ignored. Provided that the protection against electric shock is not affected, small pieces which may have broken off the

sample are ignored.

Distortion of pins and damage to the finish and small dents which do not reduce the creepage distances or clearances below the values specified in Section 11 are ignored.